Shape-Based Indicators for Mechanical Performance in Powders

작성자 정보

- Temeka 작성

- 작성일

본문

The shape of particles in powdered materials plays a pivotal role in determining their mechanical response, particularly their strength under hydrostatic pressure, shear deformation, or dynamic load. While size distribution has long been the dominant metric in powder characterization, contemporary investigations increasingly highlight that particle geometry is an comparable or superior factor in predicting bulk cohesion. The contour of individual particles affects how they compact, how loads are distributed across grain boundaries, and how promptly they distort or crack under load. To evaluate these effects, researchers have developed a suite of morphological parameters that serve as valid proxies of overall strength.

One of the most widely used metrics is the aspect ratio, which evaluates the longest dimension of a particle to its minor axis. elongated particles, such as crystals, tend to mesh tightly than isotropic ones, leading to increased shear resistance and stronger shear cohesion. However, they are also more likely to fail under axial load due to stress concentration at their ends. Conversely, ball-shaped particles pack more densely and equalize stress distribution, often resulting in increased density but weaker interparticle grip and lateral displacement.

Another important parameter is the sphericity measure, which quantifies how closely a particle matches a uniformly rounded shape. Sphericity is typically determined by comparing the external area of the particle to that of a sphere with the same volume. Increased sphericity demonstrate a clear link with enhanced powder flow and greater compaction efficiency, which in turn lead to consistent particle packing in sintered pellets. This consistency reduces porosity and voids, primary causes to crack initiation. Empirical evidence confirms that powders with near-spherical morphology often exhibit markedly enhanced durability after tablet formation compared to complex morphologies.

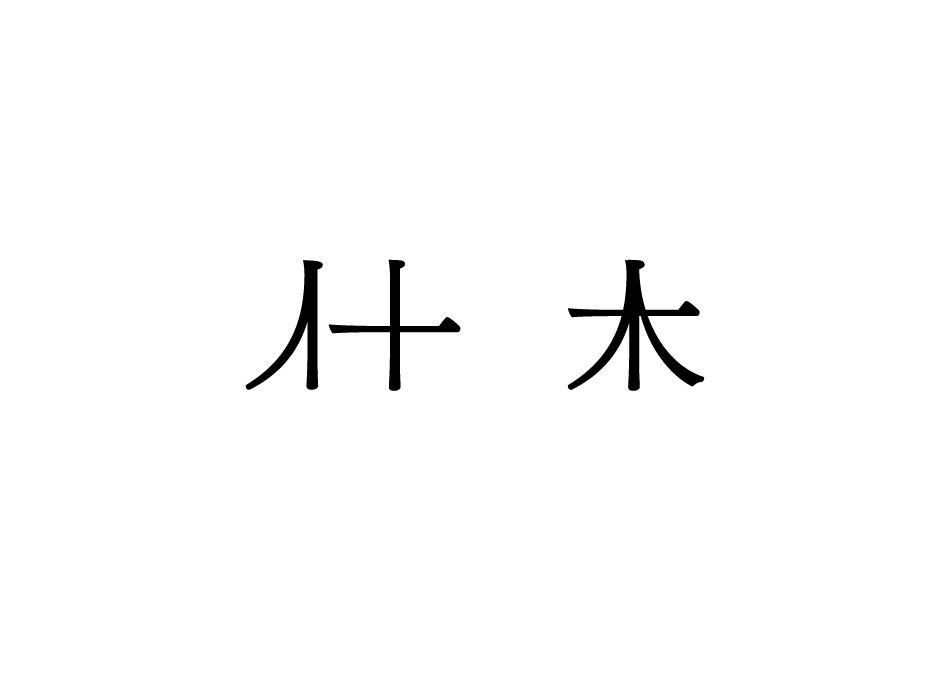

Two-dimensional sphericity, a 2D metric, 粒子形状測定 often obtained via digital imaging, evaluates the roundness of a particle’s projection. Although it does not capture full 3D structure, roundness index is a cost-effective and cost-effective metric for preliminary evaluation. Particles with high roundness demonstrate reduced surface roughness, resulting in minimal sliding resistance and even load distribution. This leads to better initial cohesion in powder metallurgy, where pre-sintering stability is indispensable before firing.

The texture of particles also plays a key role in structural integrity. Textured interfaces enhance adhesion forces and mechanical anchoring, which can enhance adhesion and reduce displacement. However, overly textured surfaces introduces crack initiation sites that may induce microcracks under load. The balance between useful interlocking and detrimental stress localization depends on the brittle-ductile transition and the strain environment. For fragile substances such as calcium phosphate, smoother surfaces generally yield improved mechanical integrity, whereas for plastic powders, optimal texture can improve sintering adhesion during heating.

More next-generation indicators, such as the roughness dimension and convexity index, are becoming mainstream in advanced characterization labs. Complexity metric measures the complexity of a particle’s outline, providing understanding into the morphological heterogeneity that affects stress transmission. A elevated roughness index often indicates a highly irregular outline capable of greater mechanical interlocking but also higher susceptibility to crack propagation. Outline convexity factor, defined as the quotient of a particle’s projected area to the area of its convex hull, indicates how much the particle strays from a smooth convex form. Significant indentations suggest the presence of cavities, which can retain voids during pressing or establish fracture-prone interfaces under load.

These particle descriptors are not used in individually but are often merged into statistical frameworks that link to mechanical response such as uniaxial compressive strength, pull-apart resistance, and stress limit. Machine learning techniques have proven highly accurate in identifying hidden patterns between geometric parameters and strength profiles. For example, random forest algorithms trained on large image datasets and corresponding compaction data have precisely modeled crack resistance with precision above 90%, beating historical dimensional metrics.

The real-world applications are significant. In industries ranging from additive manufacturing to biopharmaceutical processing, optimizing particle shape through production strategies like spray drying can significantly enhance end-use quality without reformulating ingredients. specialty manufacturers can now offer tailored particle forms that deliver predictable strength across batches, eliminating quality drift and preventing defects.

Ultimately, particle shape metrics provide a data-driven, physics-based foundation for understanding and predicting how powders behave under mechanical stress. As tools for high-resolution imaging and data processing software become more accessible, the adoption of morphological profiling into routine inspection procedures will become unavoidable. Elevating shape as a key variable to design with shape as a primary criterion enables engineers and scientists to develop stronger, more reliable powdered materials for precision manufacturing.

관련자료

-

이전

-

다음