Choosing the Right Chain for Ultra-Accurate CNC Operations

작성자 정보

- Coral Stenhouse 작성

- 작성일

본문

For applications demanding extreme positional accuracy in CNC environments the primary goal is to ensure stable, error-free motion while suppressing vibration and positional drift. In contrast to standard industrial uses that prioritize strength and longevity, CNC environments demand uncompromising positional fidelity and silent, seamless performance. The chain must maintain exact alignment across tens of thousands of operational cycles without introducing errors that could compromise part tolerances.

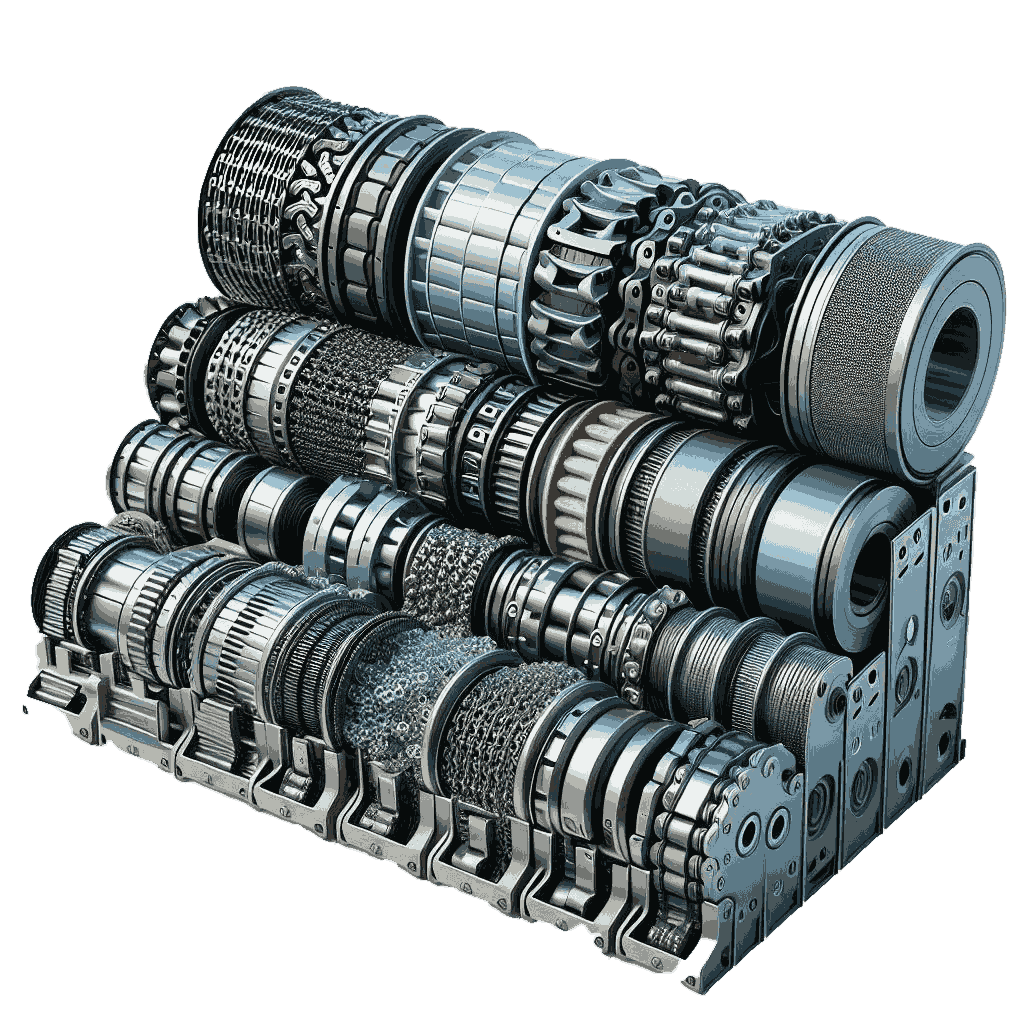

Begin with a thorough assessment of chain architecture. Roller chains are common in many machines but may not be ideal for high-precision applications due to inherent play between pins and bushings. Instead, consider precision roller chains or silent chains, which are manufactured to sub-micron specifications with minimized internal gaps. Silent chains, in particular, offer reduced acoustic noise and superior lateral tracking, making them suitable for applications where vibration control is critical.

Material selection is equally important. Stainless steel chains resist corrosion and maintain dimensional stability in environments with coolant or humidity. For nanometer-level tolerance applications, austenitic stainless with surface hardening may be preferred for their superior fatigue resistance and minimal elongation over time. Avoid standard carbon steel chains in sterile machining environments or metrology-grade systems, as they can corrode prematurely and shed metal debris.

Proper lubrication is non-negotiable. Use only low-viscosity, non-tacky precision greases that maintain lubricity without accumulating swarf or forming gummy deposits. Some premium machines integrate polymer-lined or oil-impregnated chain elements to eliminate the need for frequent maintenance and reduce the risk of contamination.

Incorrect tension directly undermines precision. Improper tension can lead to chain slack, which causes positional errors, or excessive tension, which increases bearing wear and thermal expansion. Use micro-adjustable idler assemblies with dial indicators and monitor tension dynamically with digital feedback systems. Closed-loop tension control modules suit 24.

Finally, consider the sprocket compatibility. Sprockets must align perfectly with the chain’s engagement characteristics. Even minor mismatches can cause skipping or uneven wear. Use hardened, قیمت خرید زنجیر صنعتی precision-ground sprockets made from the same high-quality materials as the chain to ensure longevity and alignment.

Proactive replacement based on elongation data prevents catastrophic drift. Chains in CNC machines should be measured for stretch using calibrated gauges, even when no surface wear is visible. A chain that has grown by more than 1 should be replaced to maintain accuracy.

The key to reliable precision lies in integrating high-tolerance components across the entire drive system. Prioritizing accuracy-focused hardware translates directly to lower rejection rates, extended tooling life, and superior surface finish consistency.

관련자료

-

이전

-

다음