Selecting the Right Chains for High-Capacity Mining Conveyors

작성자 정보

- Teddy 작성

- 작성일

본문

Picking optimal chains for demanding mineral transport systems is vital to prevent failures, reduce downtime, and ensure consistent performance. Mining operations subject conveyor components to extreme conditions including grit, water, corrosive elements, and thermal stress that can quickly degrade standard components. 7 operation.

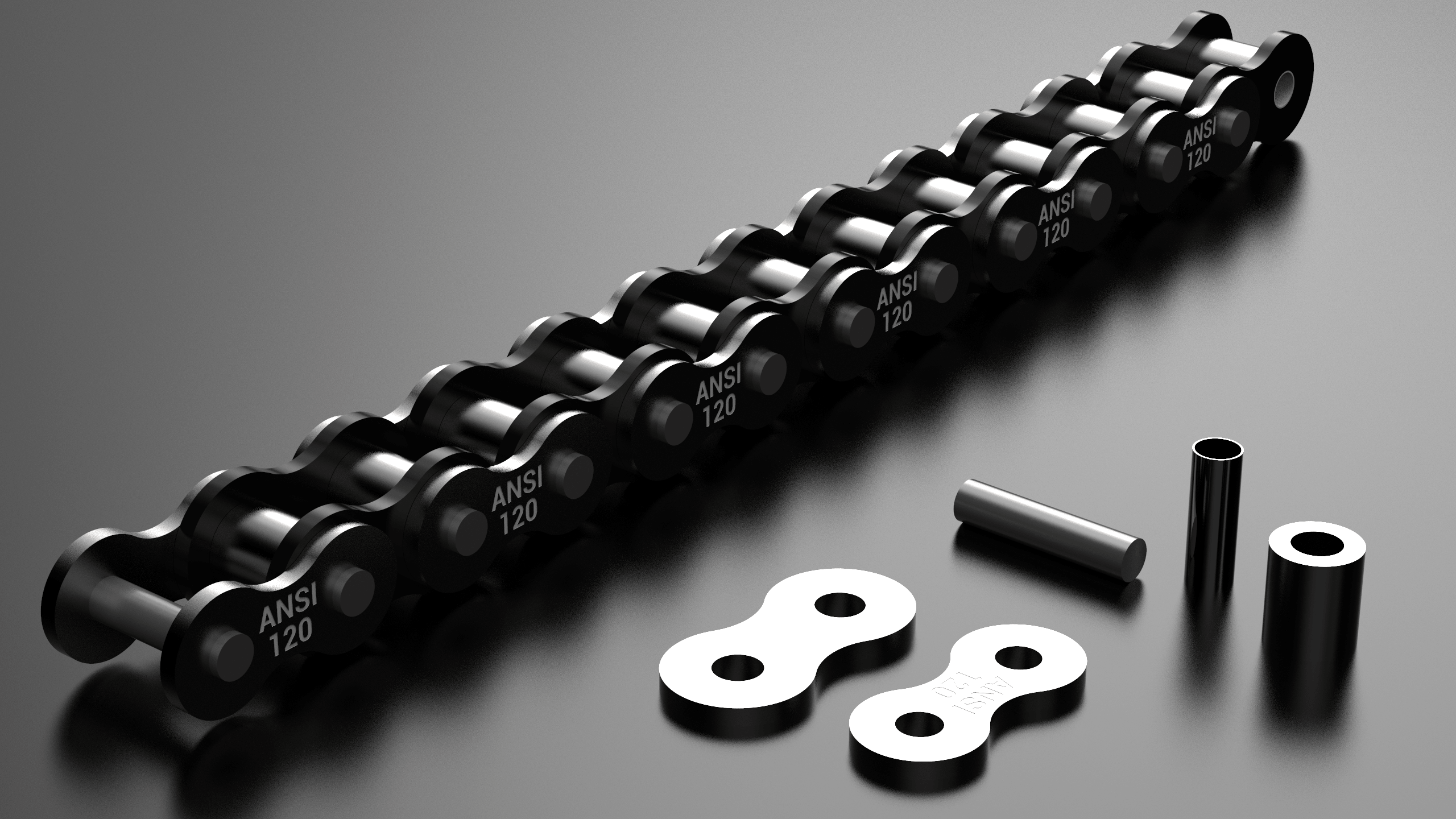

Begin by evaluating the chain configuration. Operators commonly select from roller, silent, or forged link chain variants. For heavy load applications, forged link chains are often preferred. They are made from high-strength alloy steel and can withstand shock loads and heavy impact. Thermal processing is routinely applied to increase wear resistance and prolong service life, making them ideal for moving large volumes of ore, coal, or rock.

Material selection is equally important. While stainless steel offers rust protection, it’s often overrated for mining. Carbon steel, enhanced with protective layers like zinc-nickel or ceramic coatings, delivers superior load capacity per unit weight. Hardened pivot components significantly extend service life by minimizing friction-induced degradation at critical junctions. Look for chains that have been treated with shot peening or nitriding to improve fatigue resistance.

Inadequate lubrication is a leading cause of premature failure. No chain, no matter how robust, فروش زنجیر صنعتی can survive without consistent lubricant delivery. In dusty environments, automatic lubrication systems are recommended to ensure consistent oil or grease delivery. Dry lubricants or solid film coatings can also be beneficial where traditional lubricants attract dirt and cause accelerated wear.

Selecting the correct pitch and width is critical for load compatibility and drive efficiency. Increasing pitch improves load capacity but demands larger sprockets and more mounting clearance. Oversized chains are not always better—excessive weight can strain drive systems and increase energy consumption. Always consult manufacturer load charts and factor in safety margins of at least 5 to 1 times the maximum working load.

Even the best chain fails without correct installation and disciplined maintenance. Proper tensioning prevents slack that can lead to derailment or excessive wear. Regular inspections for elongation, cracked links, or worn pins should be part of the maintenance schedule. A mere 1–2% increase in chain length can be the earliest warning of impending failure.

Select manufacturers with a documented track record in mineral processing environments. Reputable manufacturers provide detailed documentation, load ratings, and field support. Never sacrifice quality for short-term savings—substandard chains invite expensive shutdowns and serious hazards.

In mining, conveyor downtime can halt production for days. Choosing premium chains is a strategic investment, not a cost—it enables uninterrupted, secure, and productive mining.

관련자료

-

이전

-

다음