Optimizing Chain Tension for Maximum System Efficiency

작성자 정보

- Debra 작성

- 작성일

본문

The tension level in a chain drive system directly influences its operational efficiency such as pedal-powered vehicles, motorized transport, production lines, and automated equipment. When a chain is too loose, it can lose engagement with drive sprockets, leading to erratic motion and accelerated deterioration of chain and sprocket surfaces. This skipping not only reduces performance but also creates noise and vibration, which can cause premature failure of critical parts.

On the other hand, excessive tension places excessive strain on the drive components. This elevates internal resistance, requiring additional power to sustain movement and reducing overall efficiency. Over time, high tension can degrade bearing integrity and potentially fracture the chain or bend shafts. The added load also increases energy consumption, which is a major concern in industrial or long-haul environments.

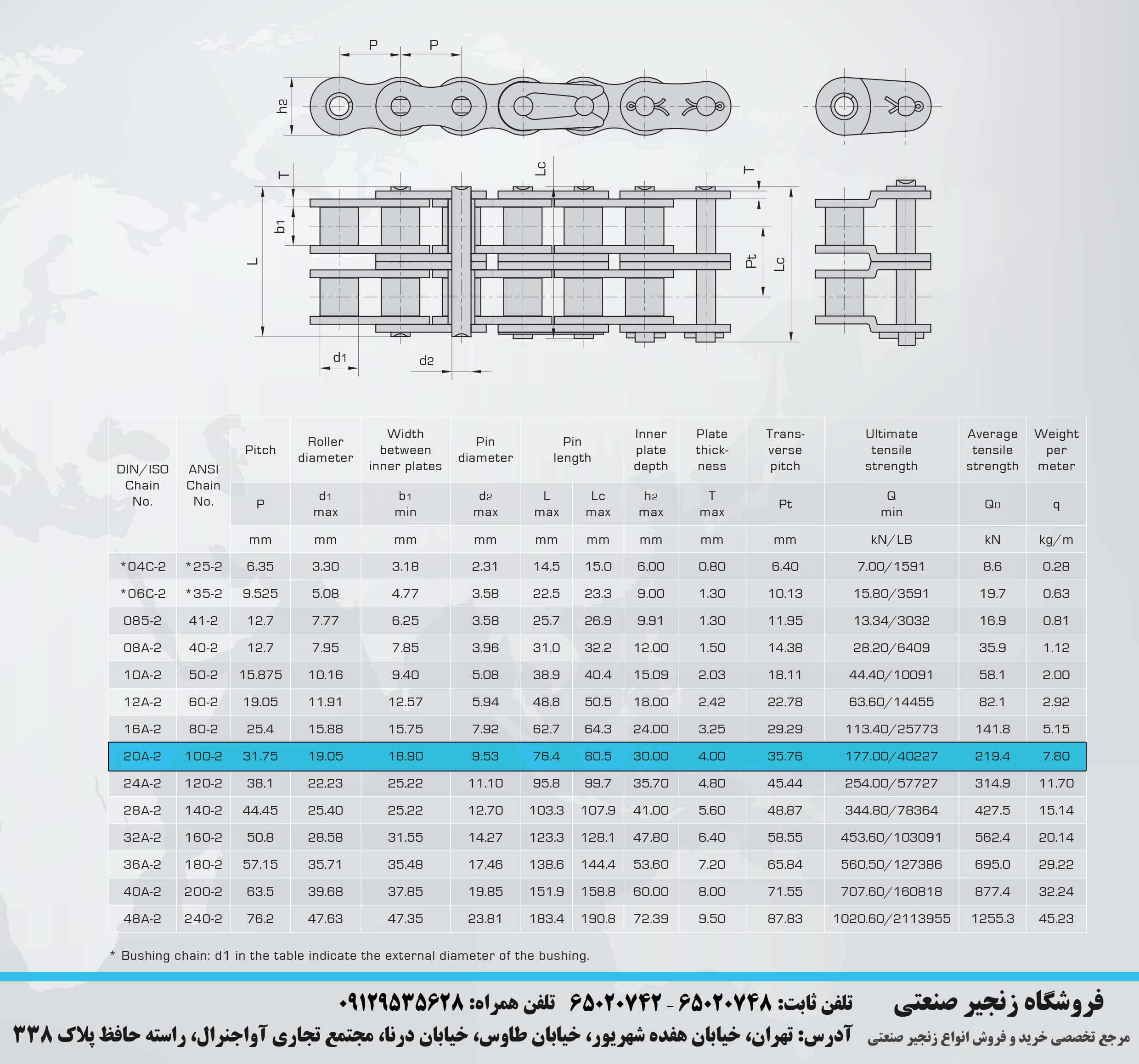

The ideal chain tension finds the optimal middle ground between looseness and tightness. Manufacturers typically provide customized tension specs for different use cases, load capacities, and operational environments. Regular maintenance and periodic tension checks are essential to ensure the chain remains within this ideal tension window. Many systems now include adaptive tension control systems to help adjust dynamically as wear occurs.

Well-adjusted chains minimize wasted power from drag and skipping, resulting in smoother operation and longer component life. In factory environments, زنجیر صنعتی this translates to reduced repair expenses and minimized production interruptions. In personal vehicles like bicycles, it means less resistance when cycling and improved MPG in engines. Ultimately, maintaining correct chain tension is a low-effort strategy with major efficiency gains, minimize running expenditures, and prolong the lifespan of critical parts.

관련자료

-

이전

-

다음