12 Polish Driving Permit For Sale Facts To Make You Think Twice About The Cooler Water Cooler

작성자 정보

- Carlo 작성

- 작성일

본문

Polish Driving Permit for Sale: Myths, Facts, and the Pathway to Legitimacy

In the age of globalization and digital transactions, acquiring a driving permit from another country has become a subject of intrigue. Amongst different driving licenses available worldwide, the Polish driving permit frequently gathers attention due to its European validity and viewed availability. However, the reality is much more complicated. This article aims to dive deep into understanding the Polish driving permit, its legitimacy, the process of obtaining it, and most importantly, unmasking the misconceptions surrounding purchasing such permits on the black market.

Understanding the Polish Driving Permit

Before going over the implications of acquiring a Polish driving permit 'for sale,' it's essential to comprehend what this document requires.

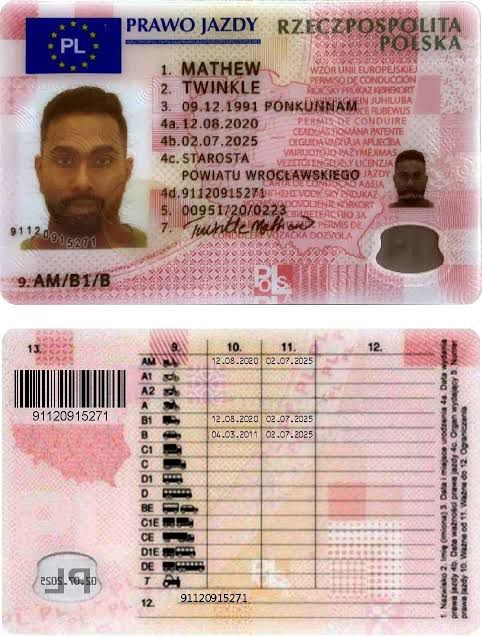

What is a Polish Driving Permit?

A Polish driving permit, or "Kup Pełne Prawo Jazdy W Polsce Proces uzyskania Polskiego Prawa jazdy," is an official document provided by the Polish federal government that gives a specific the legal right to operate a lorry in Poland Zdobądź Polskie Prawo Jazdy; Https://moparwiki.Win/, and other EU countries. The permit classifies lorry types, including guest vehicles, motorbikes, and heavy cars.

Types of Polish Driving Permits

| Permit Category | Description | Age Requirement |

|---|---|---|

| Classification B | Passenger vehicles (up to 3.5 heaps) | 18 years |

| Classification A | Bikes (approximately 125 cc) | 20 years |

| Classification C | Heavy vehicles (over 3.5 heaps) | 21 years |

| Classification D | Buses | 24 years |

How to Obtain a Polish Driving Permit

Acquiring a Polish driving permit needs following specific steps:

- Residency Requirement: You need to be a resident of Poland or have a valid status that permits you to remain.

- Medical checkup: Undergo a medical checkup to ensure you're fit to drive.

- Driving Course: Enroll in a driving school to complete the required coursework.

- Pass Tests: Successfully pass a theoretical test and a useful driving test.

- Application Submission: Submit your application along with the essential documents, including evidence of identity and home.

The Appeal of Buying a Polish Driving Permit

With the increasing demand for foreign driving permits, one might wonder why numerous consider acquiring a Polish driving permit.

Reasons for the Demand

- Travel: Strona Internetowa O Polskim Prawie Ważność Polskiego Prawa Jazdy - https://pediascape.science/wiki/Authentic_Polish_Drivers_License_The_Process_Isnt_As_Hard_As_You_Think, Many individuals want the flexibility of movement within Europe.

- Expert Needs: Driving permits are often needed for job chances, especially in transport and logistics.

- Easier Processes: Purchasing a permit may seem like a quick repair compared to the prolonged process of getting one legitimately.

The Myths of Purchasing Driving Permits

- Quick and Easy: Many think that buying a permit online is a speedy service; nevertheless, it can lead to substantial legal effects.

- Legal Alternatives: Some presume there are legal paths to 'buy' a permit legally without undergoing tests. This is not the case.

- Universal Acceptance: Many think a Polish driving permit will be accepted in all nations without more validation; nevertheless, it may not hold validity in non-EU nations.

Legal Implications and Consequences

Getting a driving permit unlawfully can result in serious legal implications, including:

- Fines: Heavy fines can be enforced on people caught utilizing deceptive documents.

- Criminal Charges: Engaging in the purchase or distribution of fake driving licenses can result in criminal charges, which might carry jail time.

- Driving Ban: Those caught may face an immediate ban from driving and additional penalties.

Contrast of Legal vs. Illegal Acquisition

| Aspect | Legal Acquisition | Illegal Acquisition |

|---|---|---|

| Cost | Varies (₤ 500 - ₤ 1,500) | Usually lower, however dangerous |

| Time Required | Numerous months | Immediate satisfaction but risky |

| Danger of Legal Trouble | Minimal | High risk of fines/jail |

| Validity | Fully genuine | Likely nonexistent |

FAQ: Purchasing a Polish Driving Permit

1. Can I legally buy a Polish driving permit online?

No, it is unlawful to purchase a driving permit online. The only legal way to obtain one is through proper channels established by Polish authorities.

2. What risks do I take if I choose to buy a permit illegally?

The dangers consist of substantial fines, legal prosecution, and a rap sheet that can impact your future.

3. Exist any legal options to obtain a Polish driving permit?

Yes, the legal path includes finishing the tests and paperwork needed by law, although it may take a while.

4. Can I use a Polish driving permit in other countries?

Yes, you can use it throughout the European Union but examine regional regulations as they may need you to exchange or confirm it, particularly after residency changes.

5. Does having a Polish driving permit affect my home nation's legal license?

It might; holding 2 licenses could produce complications concerning legal standings and requirements in your house country.

Although the allure of a Polish driving permit for sale may be appealing due to expected benefit, the legal threats and useful obstacles far outweigh any perceived advantages. It is important for individuals to understand that the most safe and most legitimate route is always through legal procedures established by the authorities.

Navigating the world of driving licenses can be made complex, and while it might seem easier to purchase one, it's necessary to pick the ideal course toward obtaining them legally. Ultimately, reliable, skilled drivers contribute to more secure roadways for everybody, and comprehending this process can be basic in accomplishing that goal.

관련자료

-

이전

-

다음